Opening Times: Mon - Fri 8.30 am - 5.00 pm

Follow us:

IRHINO COOLING TOWERS

A number of parameters describe the performance of a cooling tower.

- Range is the temperature difference between the hot water entering the cooling tower and the cold water leaving. The range is virtually identical with the condenser rise.

- Note that the range is not determined by performance of the tower, but is determined by the heat loading.

- Approach is the difference between the temperature of the water leaving the tower and the wet bulb temperature of the entering air. The approach is affected by the cooling tower capability.

- For a given heat loading, water flow rate, and entering air conditions, a larger tower will produce a smaller approach; i.e., the water leaving the tower will be colder.

- Water/Air Ratio (mw/ma) is the mass ratio of water (Liquid) flowing through the tower to the air (Gas) flow. Each tower will have a design water/air ratio.

- An increase in this ratio will result in an increase of the approach, that is, warmer water will be leaving the tower. A test ratio is calculated when the cooling tower performance is evaluated.

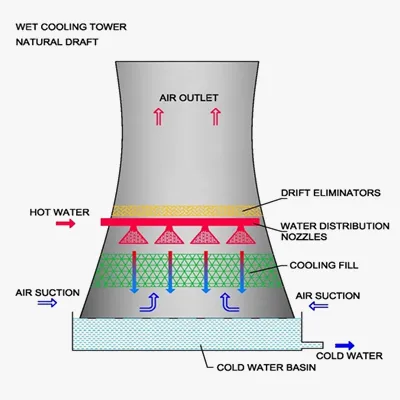

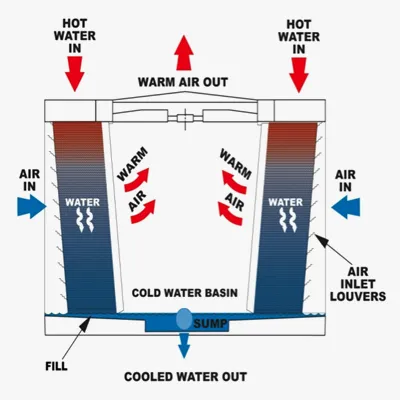

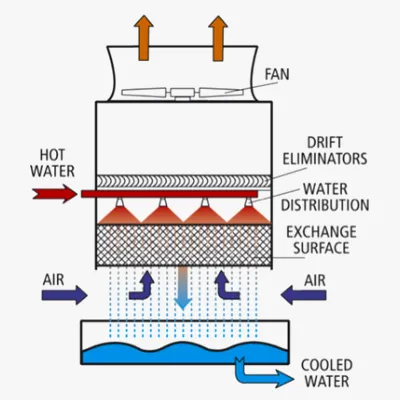

Types of Cooling Towers

Types of Fill in Cooling Towers

Splash Fill

- Prominent usage of splash-fill occurs in crossflow cooling towers, where the full-height air inlet face and open nature of the fill permits relatively easy visual inspection of the water flow pattern and the condition of the fill. In such cases, diagnosis of fill problems is greatly simplified.

- Because of the water dispersal that takes place, splash-fill cooling towers are far more forgiving of the poor initial water distribution which can result from clogged or missing nozzles, than are film-fill cooling towers. The splashing action effectively redistributes the water at each level of splash bars. The splash-fill cooling tower, however, is less affected when water-borne debris causes a deviation from the normal water flow patterns.

Film Fill

- Film-fill has gained prominence in the cooling tower industry because of its ability to expose greater water surface within a given packed volume. Approximately half of the fill used in crossflow cooling towers, and virtually all that which it utilized in counter flow cooling towers is film-type. It is equally effective in either type cooling tower.

- As can be noticed water flows in a thin “film” over vertically oriented sheets of fill which are usually spaced approximately 3/4” apart. These sheets are usually molded into corrugated or “chevron” to create a certain amount of turbulence within the air stream, and to further extend the exposed water surface. The fill pack is manufactured in a “cross-corrugated” configuration, with the contact points of the corrugated “hills” providing the proper spacing.

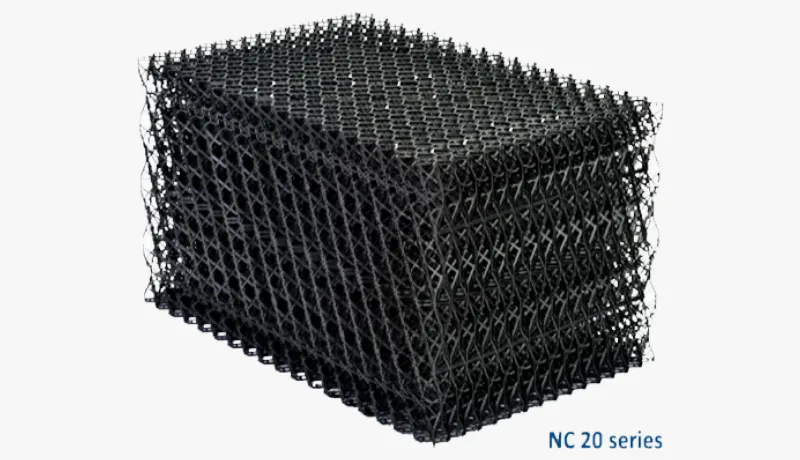

Trickle Fill

- moderately polluted water qualities. The open cross-diagonal/vertical grid structure avoid fill clogging caused by water solids and result in a low drop pressure and improve the overall cooling performance significantly.

- Combination of high water loads, low water quality and a long lifespan has been targeted with this special grid structure. The NC 20 covers 3 weights classes: 25, 27 and 48 kg/m³.

© Interfaccia 2021